In-Mold Decorations Demystified: Opening the Tricks Behind This Innovative Production Process

In today's fast-paced manufacturing landscape, in-mold decors have emerged as an innovative technique that continues to intrigue market specialists. Keep tuned as we explore the underlying principles and reveal the enigmatic allure of in-mold decors, shedding light on the keys that move this process to the center of modern-day manufacturing techniques.

The Development of In-Mold Decorations

The advancement of in-mold designs has been marked by significant innovations in technology and layout technology. In-mold decors were limited in their intricacy and color options. With the development of new manufacturing methods and materials, the possibilities have increased greatly.

One key improvement has been the advancement of high-resolution printing procedures that enable elaborate designs with lively shades to be transferred onto products throughout the molding procedure. This has allowed suppliers to achieve photorealistic photos and in-depth graphics that were previously unattainable.

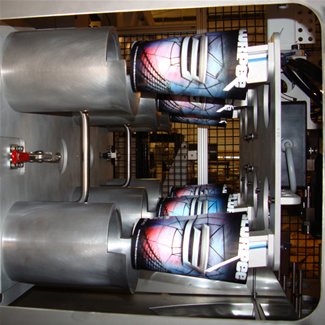

Moreover, the integration of robotics and automation in the in-mold design process has enhanced performance and uniformity in using designs to items. This not just reduces production time however additionally improves the total quality of the finished items.

Comprehending the In-Mold Refine

Marked by substantial advancements in innovation and design development, the evolution of in-mold decors has actually paved the means for a deeper understanding of the intricate process entailed in producing these decorative components. The in-mold procedure is an advanced manufacturing method where ornamental components are incorporated straight right into the last item during the molding process.

Comprehending the in-mold process requires precise control over various specifications, consisting of temperature level, stress, and timing, to guarantee the decor adheres correctly to the product. Additionally, choosing the right materials is vital to attaining top notch outcomes. By mastering the details of the in-mold procedure, makers can produce visually striking products with long lasting, lasting decorations that improve both the looks and performance of the final product.

Advantages of In-Mold Decorations

Progressing product aesthetics and resilience, in-mold decors provide a structured technique to incorporating ornamental elements throughout the production procedure. Among the crucial advantages of in-mold designs is the smooth combination of appearances, colors, and graphics straight into the product throughout the molding procedure. In-Mold Decorations. This eliminates the demand for post-production decor techniques, such as paint or printing, which can be taxing and expensive

Moreover, in-mold designs are extremely long lasting as the graphics are encapsulated within the product, making linked here them resistant to put on, scrapes, and fading. This leads to items that preserve their aesthetic charm and branding for a longer duration, even in rough settings.

Along with check my reference boosting appearances and sturdiness, in-mold decorations likewise provide enhanced layout flexibility. Manufacturers can conveniently include intricate layouts, appearances, and branding elements that would certainly be impossible or difficult to achieve with conventional decor methods.

Applications Across Industries

Throughout various sectors, in-mold designs have discovered versatile applications that improve both the visual charm and resilience of items. In addition, the home appliance industry utilizes in-mold decorations to develop trendy and durable control panels and fascia for items like fridges and ovens. Generally, in-mold designs provide a economical and effective means to improve the looks and toughness of items throughout a broad range of markets.

Future Trends in In-Mold Technology

The evolution of in-mold designs is positioned to continue shaping the landscape of item layout and manufacturing as Future Trends in In-Mold Innovation guarantee ingenious options to additionally enhance visual looks and item resilience. Among the key future patterns in in-mold innovation is the advancement of innovative products that supply enhanced toughness and versatility, enabling even more elaborate and complex layouts to be realized. Furthermore, improvements in digital printing strategies are making it possible for manufacturers to accomplish higher modification and information in in-mold decorations, opening new opportunities for innovative item designs. Another considerable trend is the integration of clever innovations, such as NFC tags or LED lighting, straight into in-mold decorations, adding interactive and useful aspects to products. The fostering of ecologically friendly products and procedures in in-mold technology is becoming progressively important, as sustainability continues to be a driving pressure in the production market. On the visit this web-site whole, the future of in-mold innovation holds wonderful possible for pressing the borders of design possibilities and enhancing the general top quality of products across different markets.

Final Thought

In-mold decorations have reinvented the manufacturing process by perfectly incorporating design components right into products. Comprehending the ins and outs of this process is vital for markets aiming to enhance their products with aesthetically attractive and long lasting designs. With its numerous benefits and versatile applications across numerous markets, in-mold modern technology is positioned to proceed evolving and shaping the future of production. Stay informed and remain ahead in this sophisticated field.

By understanding the details of the in-mold process, makers can create aesthetically striking products with long lasting, lasting decors that boost both the visual appeals and capability of the last product.

Progressing item aesthetic appeals and durability, in-mold decors provide a structured method to integrating ornamental components during the production procedure. One of the essential advantages of in-mold decors is the smooth integration of colors, textures, and graphics directly into the item throughout the molding process.The evolution of in-mold decors is positioned to continue shaping the landscape of product design and manufacturing as Future Trends in In-Mold Innovation assure cutting-edge services to additionally enhance aesthetic aesthetics and item longevity.In-mold decors have actually changed the production procedure by effortlessly integrating design aspects into items.